BK

- Efficient Cutting Heads

- Safety Device

- Precise Automatic Positioning System

- Flexible Too-Blade Combination

- Intelligent Conveyor System

- Sound Absorber Device

Product Brochure

Product Brochure BK3

- Efficient Cutting Heads

- Safety Device

- Precise Automatic Positioning System

- Flexible Too-Blade Combination

- Intelligent Conveyor System

- Sound Absorber Device

Product Brochure

Product Brochure

BK4

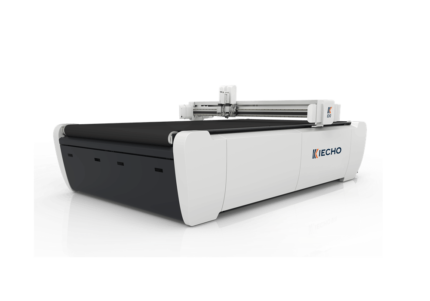

High Speed Digital Cutting System

Inherit high quality / Continue the classic

Fast / Precise / Reliable

The latest generation BK4 cutting system for single layer cutting, can work automatically and accurately process like through cut, kiss cut, milling, V groove, creasing, marking, etc. It can be widely used in the industries of Packaging, Signage, Automotive, Interior, Advertising, Apparel, Furniture and Composite, etc. BK4 cutting system with its high precision,

exibility and high e

ciency, provides automated cutting solutions to variety of industries

Product Brochure

Product Brochure

Product Brochure

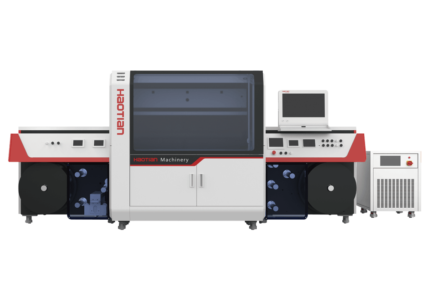

Product Brochure Digital UV Inkjet Label Printer

HTS-220/330-4~9C

CMYK+W+0+G+V (S/W) Color Group. The Self-developed 4-9-color Separation System Has A Wider Printing Color Gamut More Vivid Colors, And More Delicate Color Harmony which Further Expands The Scope Of Printing Adaptation And At The Same Time Saves On Printing Consumption, the Material Cost Also Greatly Reduces Its Ink Cost The Same Time Saves On Printing Consumption, the MaterialCost Also Greatly And It 1s Easy To Realize Full-color Printing Of Transparent And Non-transparent Materials.

Variable Data Processing System, Easily Realize Variable Data Printing Such As BarCode, QR Code, SerialN umber Dot Matrix Code, Etc. To Needs Of Anti-counterfeiting Traceability Orders.

The Patented Technology Of Automatic Nozzle Cleaning And Maintenance System (e-clean) Can Effectively Clean And Ma inta in The Nozzle Module reduce The Waste Of Maintenance Pri nthead Ink And Human Factors , To Damage The Printhead , Prolong The Service Life Of The Printhead.

Mature And Stable Circulation Ink Supply System, Modular Independent Positive And Negative Printerure Control Segmented Filter Technology Shinan's Toplnk Degassing Technology, To Ensure The Stability And Reliability Of Ink Supply.

The Printing Section Adopts Dual-servo Tension Control, Front And Rear Feeding And Unwinding Tension Control Stable And Reliable Tension Control System To Ensure Smooth Paper Feeding And Registration Accuracy.

Digital UV Inkjet Label Printer (HTS-220/330-4~9C)

1.) 4-9 sets of printing modules

A variety of printing modes are available . It can be equipped with 8 9 printing modules, and a variety of printing Processes can be realized. Easy to achieve transparent non-transparent materi aIs full color printing support Multi-plate queuing, plateless printing one print, variable data and other functions.

2.) Multi-spot color mixed printing mode

The broader color gamut supports over 9096 of pantone colors The multi-spot color mixed printing mode Makes the printing color gamut more extensive, further expands the printing scope, reduces the cost

Of ink reduces the printing process and greatly improves the efficiency.

3.) High speed/high precision/printing headHigh quality | high profile | long life

Using the world's most high-speed and high-precision industria I on-demand piezo nozzle, the speed can Reach 50M/min, the accuracy can reach 600x1200d pi, with high quality, high precision, long service life And other characteristics.

4.) Material adaptabilityReduce processes | Reduce costs

Printing is non-contact inkjet mode, no need to make coating when printing material Adaptability paper, PVC, PET, PE, BOPP, gold and silver foil and other materiaIs The surface does not need to be pre-coated reducing the process And reducing the cost .

Product Brochure

Product Brochure

Product Brochure

Product Brochure EngView Packaging Suite

EngView Packaging Suite is a CAD/CAM solution for structural design and production of boxes and POP/POS displays. It provides a wide range of tools that speed up and automate the day-to-day jobs of structural designers, graphic designers, diemakers and sales people involved in the creation, communication, and production of packaging.

The EngView packaging software is integrated with Adobe® Illustrator®. It helps professionals visualize the 3D model of the packaging with the product inside and apply graphics to the structure. With the new Step and Repeat functionality that multiplies the one-up design over the layout directly in Illustrator®, designers can generate production files with high-resolution images.

EngView Packaging Suite optimizes every aspect of the packaging design and preproduction workflows. It offers everyone the means to DREAM, CREATE and SUCCEED.

Product Brochure

Product Brochure

Product Brochure

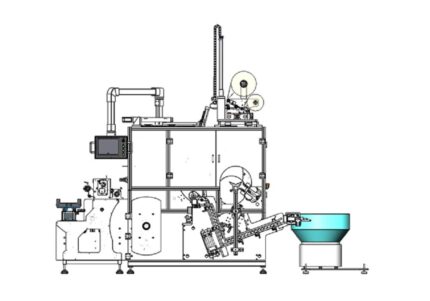

Product Brochure Flatbed Diecutting (PFD)

Main Features:-

Product Brochure

Product Brochure

- This is for sticker die- cutting .

- This machine adopts flat-bed mode,Double row high load imported bearings,independent oil supply motor,making sure the pressure stability.

- All servo motor driving for the whole machine.

- Optional:Pneumatic paper loading ,flexo printing ,cold stamping ,full-cut,rotary sheeter and so on.

Product Brochure

Product Brochure

Foil + Varnish Digital Label Printer (HGP-220/330)

PERFORMANCE AND FEATURES

- Multi-function can synchronize Foil + Varnish Digital Label Printer

- It can achieve variety of printing effects and process requirements optional nozzle XXAR and Kyocera. The thickness of varnish with

- different ink volume can be adjusted and the 3D effect of super large ink volume is very good.

- It can be used with traditional printers for secondary printing to add different special effects to ordinary labels.

Product Brochure

Product Brochure Glueless Auto Turret Rewinder (PGTR)

PGTR Automatic Glueless Turret Rewinder:

Product Brochure

Product Brochure

- Turret rewinding machine is equipped with automatic paper tube, which can realize rewinding online without stopping, and connect rotary die-cutting machine, flexo printer and other equipment.

- The rewinding machine is equipped with shear knife slitting unit with 8 knives.

- The rewinding machine is equipped with a 1 inch, 1.5 inch, 3 inch quick-release pneumatic shaft for life free of maintenance. When the rewind is replaced with different sizes of shaft, there is no need for manual mechanical adjustment system, which machine can automatically adjust the rewind size to reduce manual labor force and realize intelligent production.

- The rewinding machine is equipped with a paper core loading system, you can put paper cores into the loader, it will automatic loading cores.

- The rewinding products can be easily separated from the paper tube and will not cause damage to the printing head of the printer cartridge to the end customers. When you don’t use the turret rewind unit, you can just move them away, every friendly and flexible.

Product Brochure

Product Brochure King T

KGT-2500A+

Revolutionary Productivity Empower Packaging Competitiveness- More Stable

- Efficient Production

- Widely Used

- Wide Color Gamut

- Intelligent Paper Feeding

- Image-grade Print Quality

- Multi-grayscale Output

- High Resolution

Product Brochure

Product Brochure Laser Die Cutting (LCT)

IECHO LCT 350 laser die-cutting machine is a high-performance digital laser processing platform integrating automatic feeding, automatic deviation correction, laser flying cutting, and automatic waste removal. The platform is suitable for different processing modes such as roll-to-roll, roll-to-sheet, sheet-to-sheet, etc. It is mainly used in the process of full cutting, half cutting, flying line, punching and waste removal of non-metallic materials such as sticker, PP, PVC, cardboard and coated paper. The platform does not require cutting die, and uses electronic files import to cut, providing a better and faster solution for small orders and shorter lead times.

Product Brochure

Product Brochure

Product Brochure

Product Brochure