Who We Are?

Packnology is an initiative from a team of experts in the field of commercial printing and packaging.

With a strong domain knowledge and industry expertise, team Packnology is well equipped to help you in your journey of acquiring state of the art products and solutions to help you excel in the field of Commercial Printing & Packaging – Cartons, Labels & Pouches.

Our core team has over two decades of experience working with industry’s most renowned players including Esko, Kongsberg, Canon, Scodix, Thomson Press, Borkar Packaging and many more.

Given our know-how, we work in tandem with our customers to not only provide them with best solution, but also work closely to consult them on variety of applications. Our service structure encourages minimal down time to provide best ROI across the industry.

Our Portfolio

Our Products

PK

Product Brochure

Product Brochure TK4S

ADVANTAGES

- AKI System

- X Axis Two Motors

- Diversified Cutting Tools

- Dual Beams Cutting System

- Continuous Cutting

- Flexible Working Area

- Automatic Camera Positioning

- Higher Efficiency

- Safety Features

- Motion Control System

- Aviation Aluminum Honeycomb Panel

Product Brochure

Product Brochure BK4

Product Brochure

Product Brochure PK4

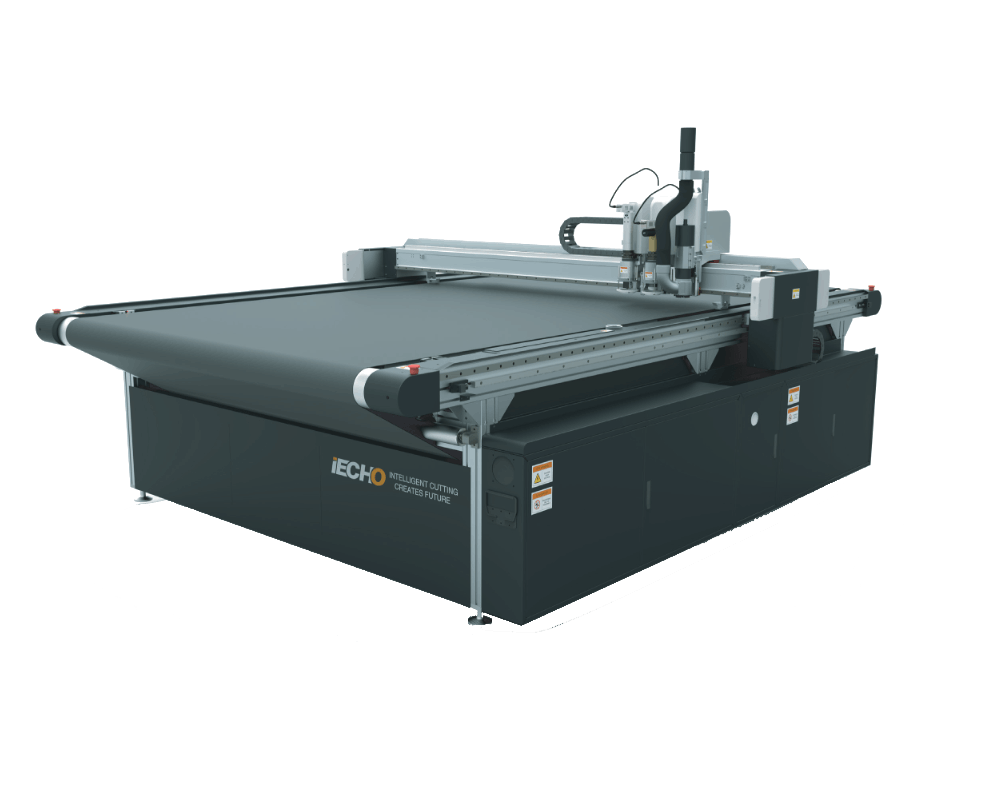

PK4 Automatic Intelligent Cutting System

PK4 automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, Printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing. Product Brochure

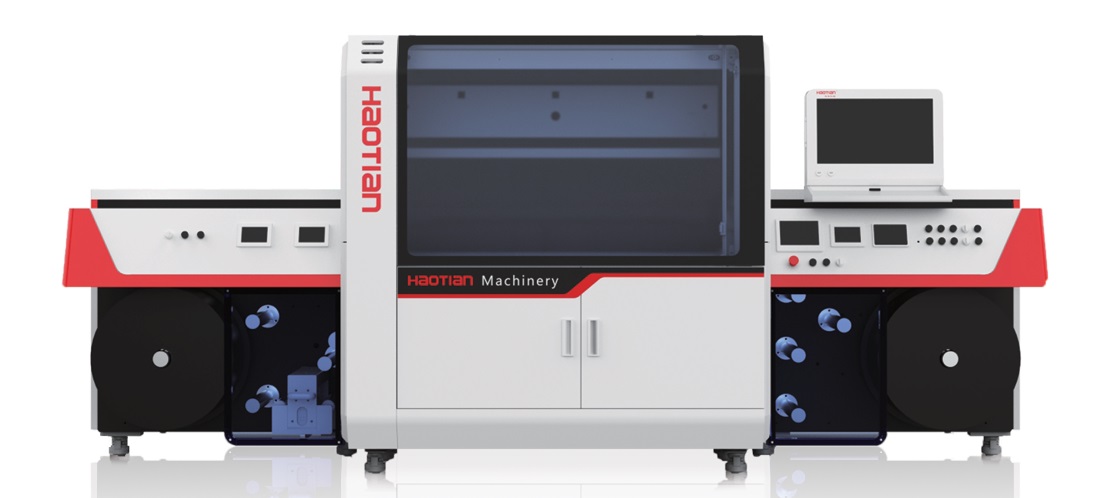

Product Brochure Digital UV Inkjet Label Printer (HTS-220/330-4~9C)

Product Brochure

Product Brochure Digital UV Inkjet Label Printer

King T

KGT-2500A+

Revolutionary Productivity Empower Packaging Competitiveness- More Stable

- Efficient Production

- Widely Used

- Wide Color Gamut

- Intelligent Paper Feeding

- Image-grade Print Quality

- Multi-grayscale Output

- High Resolution

Product Brochure

Product Brochure Laser Die Cutting (LCT)

Product Brochure

Product Brochure

PK

PK automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, Printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing.

UV INK JET DIGITAL LABEL PRINTER

LCT

IECHO LCT 350 laser die-cutting machine is a high-performance digital laser processing platform integrating automatic feeding, automatic deviation correction, laser flying cutting, and automatic waste removal. The platform is suitable for different processing modes such as roll-to-roll, roll-to-sheet, sheet-to-sheet, etc. It is mainly used in the process of full cutting, half cutting, flying line, punching and waste removal of non-metallic materials such as sticker, PP, PVC, cardboard and coated paper. The platform does not require cutting die, and uses electronic files import to cut, providing a better and faster solution for small orders and shorter lead times.

BK

Packaging textile Automotive Composites Furniture Leather

BK4

Inherit high quality / Continue the classic

Fast / Precise / Reliable

Our Partner

Our Valued Customer