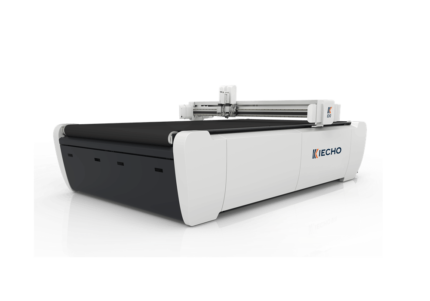

TK4S Large Format Cutting System provides best choice for multi-industries automatic processing. Its system can be precisely used for full cutting, half cutting, engraving, creasing, grooving and marking. Meanwhile, precise cutting performance could meet your large format requirement. User-friendly operating system will show you a perfect processing results.

TK4S

ADVANTAGES

- AKI System

- X Axis Two Motors

- Diversified Cutting Tools

- Dual Beams Cutting System

- Continuous Cutting

- Flexible Working Area

- Automatic Camera Positioning

- Higher Efficiency

- Safety Features

- Motion Control System

- Aviation Aluminum Honeycomb Panel

Description

Parameter

| Vacuum Pump | 1-2 Units 7.5kw | 2-3 Units 7.5kw | 3-4 Units 7.5kw |

| Beam | Single Beam | Dual Beams (Optional) | |

| MAX.Speed | 1500mm/s | ||

| Cutting Accuracy | 0.1mm | ||

| Thickness | 50mm | ||

| Data Format | DXF、HPGL、PLT、PDF、ISO、AI、PS、EPS、TSK、BRG、XML | ||

| lnterface | Serial Port | ||

| Media | Vacuum System | ||

| Power | Single phase 220V/50HZ Three phase 220V/380V/50HZ-60HZ | ||

| Operating Environment | Temperature 0℃-40℃ Humidity 20%-80%RH | ||

Size

| Length Width | 2500mm | 3500mm | 5500mm | Customized Size |

| 1600mm | TK4S-2516 Cutting Area: 2500mmx1600mm Floor Area: 3300mmx2300mm | TK4S-3516 Cutting Area:3500mmx1600mm Floor Area:430Ommx22300mm | TK4S-5516 CuttlingArea:5500mmx1600mm Floor Area:6300mmx2300mm | Based on the standard size of TK4s, can customize the machine according to customer’s special requirements. |

| 2100mm | TK4S-2521 Cutting Area:2500mmx210omm Floor Area:3300mmx2900mm | TK4S-3521 CuttingArea:3500mmx2100mm Floor Area: 430Ommx290Omm | TK4S-5521 CuttingArea:5500mmx2100mm Floor Area:6300mmx2900mm | |

| 3200mm | TK4S-2532 Cutting Area: 2500mmx3200mm Floor Area: 3300mmx4000mm | TK4S-3532 Cutting Area:35oommx3200mm Floor Area: 4300mmx4000mm | TK4S-5532 CuttingArea:5500mmx3200mm Floor Area: 6300mmx4000mm | |

| Other Sizes | TK4S-25265 (L*W)2500mm×2650mm Cutting Area: 2500mmx2650mm Floor Area:3891mm x3552mm | TK4S-1516(L*W)1500mm×1600mm CuttingArea:1500mmx1600mm Floor Area:2340mm x 2452mm | ||

Shipping & Delivery

Related products

BK3

- Efficient Cutting Heads

- Safety Device

- Precise Automatic Positioning System

- Flexible Too-Blade Combination

- Intelligent Conveyor System

- Sound Absorber Device

Product Brochure

Product Brochure

BK4

High Speed Digital Cutting System

Inherit high quality / Continue the classic

Fast / Precise / Reliable

The latest generation BK4 cutting system for single layer cutting, can work automatically and accurately process like through cut, kiss cut, milling, V groove, creasing, marking, etc. It can be widely used in the industries of Packaging, Signage, Automotive, Interior, Advertising, Apparel, Furniture and Composite, etc. BK4 cutting system with its high precision,

exibility and high e

ciency, provides automated cutting solutions to variety of industries

Product Brochure

Product Brochure

Product Brochure

Product Brochure EngView Packaging Suite

EngView Packaging Suite is a CAD/CAM solution for structural design and production of boxes and POP/POS displays. It provides a wide range of tools that speed up and automate the day-to-day jobs of structural designers, graphic designers, diemakers and sales people involved in the creation, communication, and production of packaging.

The EngView packaging software is integrated with Adobe® Illustrator®. It helps professionals visualize the 3D model of the packaging with the product inside and apply graphics to the structure. With the new Step and Repeat functionality that multiplies the one-up design over the layout directly in Illustrator®, designers can generate production files with high-resolution images.

EngView Packaging Suite optimizes every aspect of the packaging design and preproduction workflows. It offers everyone the means to DREAM, CREATE and SUCCEED.

Product Brochure

Product Brochure

Product Brochure

Product Brochure Laser Die Cutting (LCT)

IECHO LCT 350 laser die-cutting machine is a high-performance digital laser processing platform integrating automatic feeding, automatic deviation correction, laser flying cutting, and automatic waste removal. The platform is suitable for different processing modes such as roll-to-roll, roll-to-sheet, sheet-to-sheet, etc. It is mainly used in the process of full cutting, half cutting, flying line, punching and waste removal of non-metallic materials such as sticker, PP, PVC, cardboard and coated paper. The platform does not require cutting die, and uses electronic files import to cut, providing a better and faster solution for small orders and shorter lead times.

Product Brochure

Product Brochure

Product Brochure

Product Brochure Magnetic Rotary Die Cutting ( MCT)

With a small floor space and easy operation, the MCT series Rotary Die Cutter is an intelligent die-cutting machine for small batch and multiple repeat production, widely used for self-adhesive stickers, wine labels, garment hangtags, playing cards and other products in printing & packaging, clothing and electronics industries. With a fish-scale feeding platform, automatic deflection and precise alignment, the sheet passes quickly through the high-strength rolls equipped with magnetic blades and completes a variety of die-cutting processes such as full-cutting, half-cutting, perforating, creasing and easy-tear lines (toothed lines).

Product Brochure

Product Brochure

Product Brochure

Product Brochure PK

PK automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, Printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing.

Product Brochure

Product Brochure

Product Brochure

Product Brochure PK4

PK4 Automatic Intelligent Cutting System

PK4 automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, Printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing. Product Brochure

Product Brochure Semi-automatic Gluing Machine SH-ZHJ110

MAIN FEATURES

- Available for Cardboard Box, Cprrugated Board, Display Stand, Wooden Box, etc. especially for Window Box / Special shape window box

- Hot melt glue and cold glu both available.

- Debugging in 1 minute Teaching system supported, user friendly.

- Perform one time of action and then repeat movement by memory.

- Gluing could be adjusted and controlled to be in Dots or Lines, save more than 40 glue.

Product Brochure

Product Brochure