Material shortage alarm

Feeding end is detected by a photoelectric ’’ sensor, and the machine automatically stops running and alarms when there is no paper.

High speed cutting

The cutting laser line speed can reach 8 000 mm/s, and the mdximum feeding speed can reach 90 m/min.

Simple automation

CAM/CAD computer control only requires the input of cutting files in the software. Chanpe the cut shape on the fly.

Quick switch

No need for a mold, you can cut your design product at any time. No need to wait.

QR code scanning supports dynamic image change

The best partner for digital printing presses.

Flexible and Multipurpose

Full cut, half cut, perforated, engraved, marked, multiple functions.

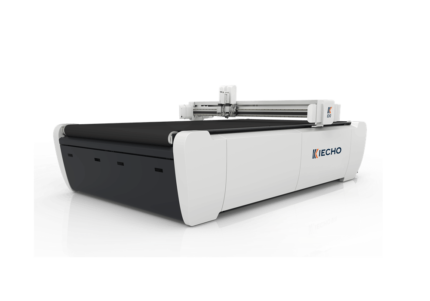

Product Brochure

Product Brochure