Magnetic Rotary Die Cutting ( MCT)

With a small floor space and easy operation, the MCT series Rotary Die Cutter is an intelligent die-cutting machine for small batch and multiple repeat production, widely used for self-adhesive stickers, wine labels, garment hangtags, playing cards and other products in printing & packaging, clothing and electronics industries. With a fish-scale feeding platform, automatic deflection and precise alignment, the sheet passes quickly through the high-strength rolls equipped with magnetic blades and completes a variety of die-cutting processes such as full-cutting, half-cutting, perforating, creasing and easy-tear lines (toothed lines).

Product Brochure

Product Brochure

Product Brochure

Product Brochure Mannat ERP

Mannat is developed by MPMS which is a venture of Printing Technologists who have 20+ years of experience in the Printing Industry. Although many ERP solutions are available world wide for Printing & Packaging Industry but most of the ERPS fail due to their complicated user interface as they are mostly developed by IT professionals who lack in-depth knowledge of the trade.

Product Brochure

Product Brochure

Product Brochure

Product Brochure Multifunctional Label finishing Printer (PMFM)

PMFM 330/420/520 Integrated Multi-Functional Digital Finishing System

Machine features:

Product Brochure

Product Brochure

- Modular design

- Full servo control of the whole machine

- Intermittent screen-printing unit

- Intermittent flatbed hot stamp and emboss unit, which can be 90° rotated

- Optional: positioning hologram

- Intermittent flexo printing unit can do flexo printing, cold foil, varnish, lamination,

- Drying system optional: UV or LED-UV

- Intermittent flexo unit can switch between full and semi-rotary mode

- Intermittent die-cutting unit can switch between full and semi-rotary mode,

- Standard: Shear/Razor knife, Optional: Crush knife; Auto slitting, automatic back

- Double servo rewind shaft, can rewind forward and reverse

- Online monitor and diagnosis

- Optional: corona and dust removal device; IML function

Product Brochure

Product Brochure PK

PK automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, Printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing.

Product Brochure

Product Brochure

Product Brochure

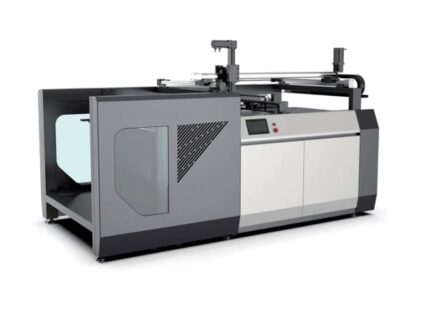

Product Brochure PK4

PK4 Automatic Intelligent Cutting System

PK4 automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform. Equipped with various of tools, it can quickly and precisely make through cutting, half cutting, creasing and marking. It is suitable for sample making and short-run customized production for Signs, Printing and Packaging industries. It is a cost-effective smart equipment that meets all your creative processing. Product Brochure

Product Brochure Semi-automatic Gluing Machine SH-ZHJ110

MAIN FEATURES

- Available for Cardboard Box, Cprrugated Board, Display Stand, Wooden Box, etc. especially for Window Box / Special shape window box

- Hot melt glue and cold glu both available.

- Debugging in 1 minute Teaching system supported, user friendly.

- Perform one time of action and then repeat movement by memory.

- Gluing could be adjusted and controlled to be in Dots or Lines, save more than 40 glue.

Product Brochure

Product Brochure Semi-automatic Gluing Machine With Paper Feeding (SH-ZHJ1000/1500)

MAIN FEATURES

- Automatic positioning and paper feeding, no more manual work required.

- No need to add silk screen mould for gluing window boxes stick.

- Teaching system in supported to adjust machine. Easy to learn and operate.

- Accurate painting glue, uniform gluing

Product Brochure

Product Brochure Slitter with Dual Rewinder & Inspection (PLSR2)

P-SLR2 inspection slitting machine

( without camera system, without semi-turret )

Product Brochure

Product Brochure

Product Brochure

Product Brochure Slitter with turret rewinder (PLSR2)

Machine features:

Product Brochure

Product Brochure

- Servo driven unwinder

- Precise unwind tension control

- Reel end detector

- Electronic web guide with ultrasonic web sensor

- Servo driven precision slitting cassette

- Precise slitting tension control

- Quick exchange cassette for setup outside the rewinder

- During production to reduce setup time and waste

- Trim waste extraction fan

- Easy access splice table with web clamps

- Semi-automatic, servo driven turret rewinder

- Automatic slow down, stop & turn at selected reel diameter or

- Label count for significant increase in productivity

- Exchangeable shafts for various diameters

- User friendly 7” touch screen HMI, job archive (>500 settings) to reduce setup time

Product Brochure

Product Brochure