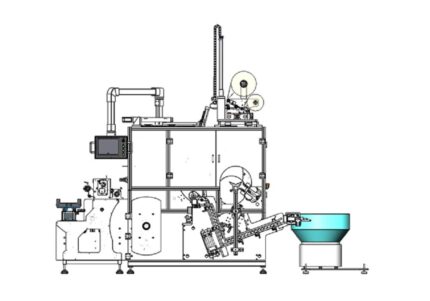

Flatbed Diecutting (PFD)

Main Features:-

- This is for sticker die- cutting .

- This machine adopts flat-bed mode,Double row high load imported bearings,independent oil supply motor,making sure the pressure stability.

- All servo motor driving for the whole machine.

- Optional:Pneumatic paper loading ,flexo printing ,cold stamping ,full-cut,rotary sheeter and so on.

Description

Specifications:-

| Max.Web Width: | 450mm |

| Max.Die cutting Width | 440 mm |

| Max. Die cutting length | 450mm |

| Machinery speed | 80-400 times/min |

| Max. Stamping width | 440mm(oprtional) |

| Max.Stamping length | 420mm(optional) |

| Die cutting precision | ±0.15mm |

| Max unwinding diameter

|

650mm |

| Max rewinding diameter

|

650mm |

| Dimension | 3200mm × 1280mm × 1650mm (single station)

4500*1280*1650mm(double station) |

| Weight | 3200KGS |

| Die cutting upper plate | Standard 1 pc(extra optional) |

| Die cutting down plate | Standard 1 pc(extra optional) |

| Stamping upper plate | Standard 1 pc(extra optional) |

| Stamping down plate | Standard 1 pc(extra optional) |

Shipping & Delivery

Related products

Glueless Auto Turret Rewinder (PGTR)

PGTR Automatic Glueless Turret Rewinder:

Product Brochure

Product Brochure

- Turret rewinding machine is equipped with automatic paper tube, which can realize rewinding online without stopping, and connect rotary die-cutting machine, flexo printer and other equipment.

- The rewinding machine is equipped with shear knife slitting unit with 8 knives.

- The rewinding machine is equipped with a 1 inch, 1.5 inch, 3 inch quick-release pneumatic shaft for life free of maintenance. When the rewind is replaced with different sizes of shaft, there is no need for manual mechanical adjustment system, which machine can automatically adjust the rewind size to reduce manual labor force and realize intelligent production.

- The rewinding machine is equipped with a paper core loading system, you can put paper cores into the loader, it will automatic loading cores.

- The rewinding products can be easily separated from the paper tube and will not cause damage to the printing head of the printer cartridge to the end customers. When you don’t use the turret rewind unit, you can just move them away, every friendly and flexible.

Product Brochure

Product Brochure Multifunctional Label finishing Printer (PMFM)

PMFM 330/420/520 Integrated Multi-Functional Digital Finishing System

Machine features:

Product Brochure

Product Brochure

- Modular design

- Full servo control of the whole machine

- Intermittent screen-printing unit

- Intermittent flatbed hot stamp and emboss unit, which can be 90° rotated

- Optional: positioning hologram

- Intermittent flexo printing unit can do flexo printing, cold foil, varnish, lamination,

- Drying system optional: UV or LED-UV

- Intermittent flexo unit can switch between full and semi-rotary mode

- Intermittent die-cutting unit can switch between full and semi-rotary mode,

- Standard: Shear/Razor knife, Optional: Crush knife; Auto slitting, automatic back

- Double servo rewind shaft, can rewind forward and reverse

- Online monitor and diagnosis

- Optional: corona and dust removal device; IML function

Product Brochure

Product Brochure Slitter with Dual Rewinder & Inspection (PLSR2)

P-SLR2 inspection slitting machine

( without camera system, without semi-turret )

Product Brochure

Product Brochure

Product Brochure

Product Brochure Slitter with turret rewinder (PLSR2)

Machine features:

Product Brochure

Product Brochure

- Servo driven unwinder

- Precise unwind tension control

- Reel end detector

- Electronic web guide with ultrasonic web sensor

- Servo driven precision slitting cassette

- Precise slitting tension control

- Quick exchange cassette for setup outside the rewinder

- During production to reduce setup time and waste

- Trim waste extraction fan

- Easy access splice table with web clamps

- Semi-automatic, servo driven turret rewinder

- Automatic slow down, stop & turn at selected reel diameter or

- Label count for significant increase in productivity

- Exchangeable shafts for various diameters

- User friendly 7” touch screen HMI, job archive (>500 settings) to reduce setup time

Product Brochure

Product Brochure